Finding chocolate with clean and minimal ingredients is very difficult. All chocolates besides the 3 listed below have soy, metals, bugs, wax, blood, additives, and a whole list of ingredients we can’t pronounce. Try these 3 chocolates and you won’t touch any other brand – It’s the Truth!

- Hu has both non dairy and dairy selections which can be found at sprouts, wholefoods, amazon and their main website.

- Ingredients: check the website, it depends on which chocolate you like.

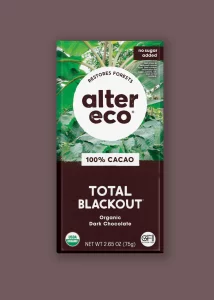

- Altereco Total Blackout is for those who like straight 100% cocoa with no other ingredients. It is an acquired taste. It can be found at sprouts, gelsons, wholefoods, amazon, ralphs or their main website.

- Ingredients: organic cocoa bean and organic cocoa butter.

- Milkboy Switzerland is a milk chocolate with minimal ingredients. It is heavenly! It can be found at wholefoods, sprouts, amazon or their main website.

- Ingredients: sugar, whole milk powder, cocoa butter, cocoa mass, vanilla pods, emulsifier (sunflower lecithin)

- Sunflower lecithin is a promotes digestive health. (Future post on the different types of lecithin)

- Ingredients: sugar, whole milk powder, cocoa butter, cocoa mass, vanilla pods, emulsifier (sunflower lecithin)

For those who would like to read about the steps in chocolate making.

Harvesting Cocoa

Step #1: Plucking and opening the Pods

Cocoa beans grow in pods that sprout off of the trunk and branches of cocoa trees. The pods are about the size of a football. The pods start out green and turn orange when they’re ripe. When the pods are ripe, harvesters travel through the cocoa orchards with machetes and hack the pods gently off of the trees.

After the cocoa pods are collected into baskets, the pods are taken to a processing house. Here they are split open and the cocoa beans are removed. Pods can contain upwards of 50 cocoa beans each. (The beans are not brown yet, they are white)

Step #2: Fermenting the cocoa seeds

Now the beans undergo the fermentation processing. They are either placed in a large, shallow, heated tray or covered with large banana leaves. If the climate is right, they may be simply heated by the sun. Workers come along periodically and stir them up so that all the beans come out equally fermented. During fermentation is when the beans turn brown. This process may take 5-8 days.

Step #3: Drying the cocoa seeds

After fermentation, the cocoa seeds must be dried before they can be scooped into sacks and shipped to chocolate manufacturers. Farmers simply spread the fermented seeds on trays and leave them in the sun to dry. The drying process usually takes about a week and results in seeds that are about half of their original weight.

Manufacturing Chocolate

Step #1: Roasting and Winnowing the cocoa

The first thing that chocolate manufacturers do with cocoa beans is roast them. This develops the color and flavor of the beans. The outer shell of the beans is removed, and the inner cocoa bean meat is broken into small pieces called “cocoa nibs.” The roasting process makes the shells of the cocoa brittle, and cocoa nibs pass through a series of sieves, which strain and sort the nibs according to size in a process called “winnowing”.

Step #2: Grinding the cocoa nibs

Grinding is the process by which cocoa nibs are ground into ” cocoa liquor”. The grinding process generates heat and the dry granular consistency of the cocoa nib is then turned into a liquid as the high amount of fat contained in the nib melts. After this step is where it gets bad… companies add non-organic dairy, soy lecithin or different type of lecithin, refined sugars, chemicals, colors, flavors etc. Stay tuned for my soy blog which will expose how toxic this genetically modified Bill Gates invented crop is to our organs.

The Basic Blends:

Milk Chocolate – sugar, milk or powder, cocoa powder, cocoa liquor, cocoa butter, lecithin and vanillin.

White Chocolate – sugar, milk or milk powder, cocoa liquor, cocoa butter, lecithin and vanillin.

Dark Chocolate – cocoa powder, cocoa liquor, cocoa butter, sugar, lecithin and vanillin.

After blending is complete, molding is the final procedure for chocolate processing. This step allows cocoa liquor to cool and harden into different shapes depending on the mold. Finally the chocolate is packaged and distributed around the world.